1 Lac - 25 Lac / Pack

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Type | Zero Liquid Discharge Systems, Effluent Treatment Plant |

| Certification | Self |

| Color | Grey |

| Click to view more | |

Product Details

Voltage

220V

Condition

New

Function

Packing

Automatic Grade

Semi Automatic

Power

9-12kw

Packaging Type

Cartons

Driven Type

Electric, Mechanical

Weight (Kg)

100-1000kg

Brand Name

Braj Projects Pvt.Ltd.

Application

Zero Effluent Discharge-

Power Source

Grid 220 V, Pump And Compressor

After-Sales Service Provided

Yes

Process

Very Simple Installation

Installation Service

Yes

Industry

Sugar Industry

Material

Carbon Steel

Feed Flow Rate

0 - 50 m3/day

Port

ANY

Payment Terms

T/T, Other

Delivery Time

2 weeks

Braj Projects Pvt.Ltd., every plant is tailor – designed to suit various process conditions like; Feed Temp, Feed Concentration, Product Concentration and Characteristics of Material like Heat Sensitivity, Flow Characteristics, Corrosion & Scaling tendencies.

Details :

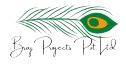

- Steam always enter the first heater. Vapors from the first evaporator are fed to the second heater and so on. The heaters transfer heat indirectly.

- The vapor liquor mixture enters the flash vessel & gets separated in 3 – stage separation program and more or less pure water vapors enter the 2nd stage, guaranteeing quality of condensate to be recycled. The concentrated liquor enters the 2nd heater, gets heated by indirect contact with the generated vapors and the same procedure is repeated.

- The overall result of such meticulous design is very encouraging in these days of high energy costs and the Processing Costs on our Evaporation Plants are un-matched in the Industry.

- When the liquor contains soluble organic or inorganic contents, they tend to separate out when solubility is reduced because of either increase in concentration or decrease in temperature or both.

- The total characteristics of the effluent are seldom known or even if known keep changing as per the product mix. Due to this inconsistent feed quality, there are very high chances of tube fouling and maintenance operations.

- If the separated solids / crystals are not taken care of properly, they will choke Evaporator, piping or Exchanger tubes. Consequent excessive scaling also would call for stoppages for cleaning.

- Since Evaporation systems are susceptible to fouling as described above, there is a limitation to the achievable concentration of the product in an evaporator.

- Usually most of the salts start crystallizing / scaling after about 27% concentration. So to reduce downtime and cleaning costs, it is best suggested to concentrate the effluent in the forced circulation evaporator up to a concentration depending upon the nature of effluents and then take it for further processing : Crystallization / solidification, depending upon the nature of salt.

Post Evaporation Drying :

Based on the available infrastructure and the pollution norms various Post evaporation methods are employed by industries are as follows :

- Solar Pond

- Crystalliser & Centrifuge

- Thickener

- Agitated Thin Film Dryer

- Spin Flash Dryer

- Spray Dryer

Looking for "Zero Discharge Effluent Plant" ?

Pack(s)

Explore More Products