| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Download | |

| Voltage | 240 - 320V |

| Automatic Grade | Automatic |

| Click to view more | |

Product Details

In such grim situation one has to really start thinking a fresh on various profit making avenues which were being ignored in better times. The ideal way of looking at it is basically looking at points to save wastages of various resources and recover it profitably wherever possible.

Details :

Braj Projects Pvt.Ltd. has a team who have an experience of More then 10 Years in recovery from waste offering various projects such as heat recovery systems ,salt recovery and caustic recovery system / caustic recovery plant

Explanation :

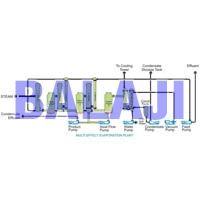

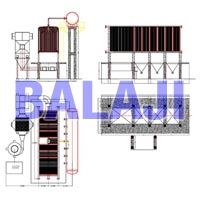

Mercerisers for Textile Mills generate dilute caustic liquor, which if drained to effluent treatment plant, will create considerable problems in meeting the environmental standards. Caustic recovery system / caustic soda recovery plant by concentrating wash liquor and using the same back in Merceriser is the only feasible solution.

Principle :

Under caustic recovery system / caustic soda recovery , Caustic at low concentration is heated to its boiling point with the help of a heat source and the vapors generated due to boiling are used to heat the weak liquor. This hot liquid is then flashed at lower pressure and the vapors so generated used again. The weak liquor is concentrated to 250-300 GPL as in case of dry Merceriser or 450-500 GPL in case of wet Merceriser which can be reused with a minor topping up of caustic.

Operation :

- Weak Caustic lye, around 5-6 Be ( 40 - 50 gpl ), is collected from the impregnation and washing chamber into a storage tank. It is then taken to a filtration unit to filter the suspended solids, fluff etc. The feed to CRP then passes through a series of preheaters which preheat the wash liquor with the help of flash vapors from the condensate flashes ensuring minimum steam loss in heating the Wash liquor to its boiling point.

The liquor in the tubes comes in contact with the steam in the shell side of heater 1 and the liquor starts boiling. The vapor liquor mixture enters the flash vessel through a tangential entry and the vapors get separated and enter the shell of the 2nd stage. - The boiling in the successive effect takes place due to lower pressure created with help of a water ring vacuum pump. Due to lower pressure the boiling point of the liquor is reduced and it starts boiling.

- The concentrated liquor enters the 2nd heater due to the pressure difference and comes in indirect contact with the generated vapors and the same procedure is repeated. The concentrated product is removed from the last stage by a product pump.This later is taken either to a storage tank or to a Concentrated Lye purification system .

- Under caustic recovery system / caustic soda recovery plant vapors generated at the last stage need to be condensed. This is done by either HotWateror an Adiabitc Evaporatorsystem. In case of a hot water system, water at room temperature is passed through tubes of an exchanger and it gets hot due to the vapors. This hot water is uncontaminated and hence can safely be used in the process or the boiler as per the requirement.

- In some cases where the hot water generated cannot be effectively consumed the effluent is passed through the exchanger and sprayed in an Adiabatic Evaporator Here the waste heat is lost in form of vapors and hence effective steam consumption of steam is reduced. Also nuisance of excess hot water is eliminated.

Looking for "caustic recovery plant" ?

Explore More Products